SEAT

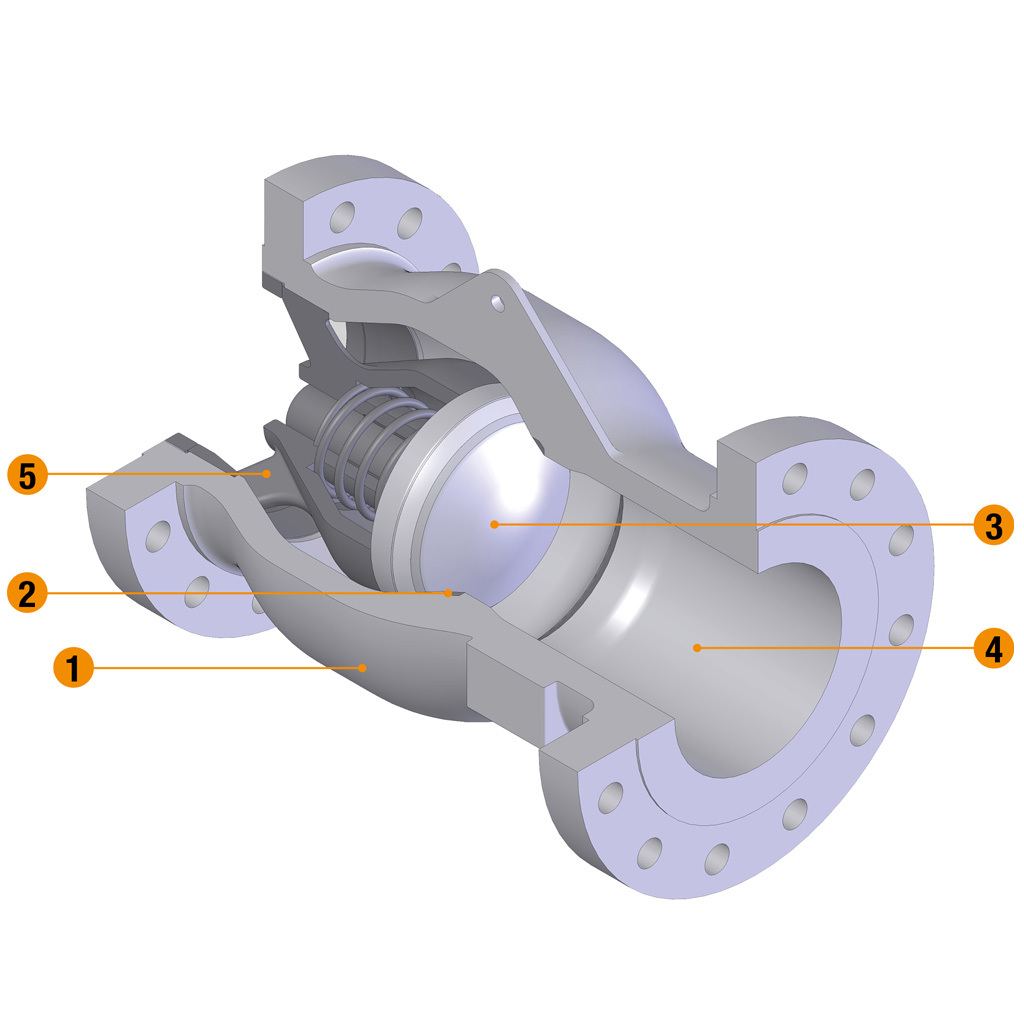

The seat ring is part of the trim. It can be integral with the body or renewable. A ground lapped surface allows the tightness.

As per ORION standard, the spring is sized for horizontal and vertical (downward-upward flow) installation, but it shall be properly sized to match specific installation, especially on larger valves where heavy discs are involved. An arrow is cast embossed on the body of the valve, indicating the fluid direction. Check anyway with ORION if the valve is suitable for the desired installed position.

The body is cast or forged in carbon or stainless steel and is also available in many other CRA. For severe services and large valve sizes it can be internally lined or fully cladded instead of having solid CRA. The internal profile is designed in order to minimize pressure losses, and basic dimensions (face to face and wall thickness) comply with API 6D and ASME B16.34 standards. Body connections can be provided as per ASME B 16.5 RF or RTJ, as well as BW end or hub connection are available.

The seat ring is part of the trim. It can be integral with the body or renewable. A ground lapped surface allows the tightness.

The disc is the main part of the trim and allows fluid control. It comes in forged steel and in cast steel. Its shape is carefully designed in order to avoid turbulences and is assisted by a spring in closed position.

The valve will be closed quickly at fluid stop and reversal, giving its peculiar NON SLAM EFFECT, avoiding any reverse acceleration of fluid and consequent water-hammer. Selection of spring characteristics can be made upon engineering evaluation of specific applications.

The diffuser supports the disc and spring assembly and lets the fluid exiting from the valve with minor impact on pressure drop.