GLAND AND FLANGE

They are in forged steel and are supplied in two pieces, self aligning design in order to allow the gland to slide parallel to the stem even if the eyebolts are unevenly tightened.

A lantern ring is supplied upon request, in this case the stuffing box shall be drilled, tapped and fitted with an 1/4” NPT plug or grease fitting.

Valves are best fit for vertical stem / horizontal flow installation. Special cases can be evaluated and developed on request.

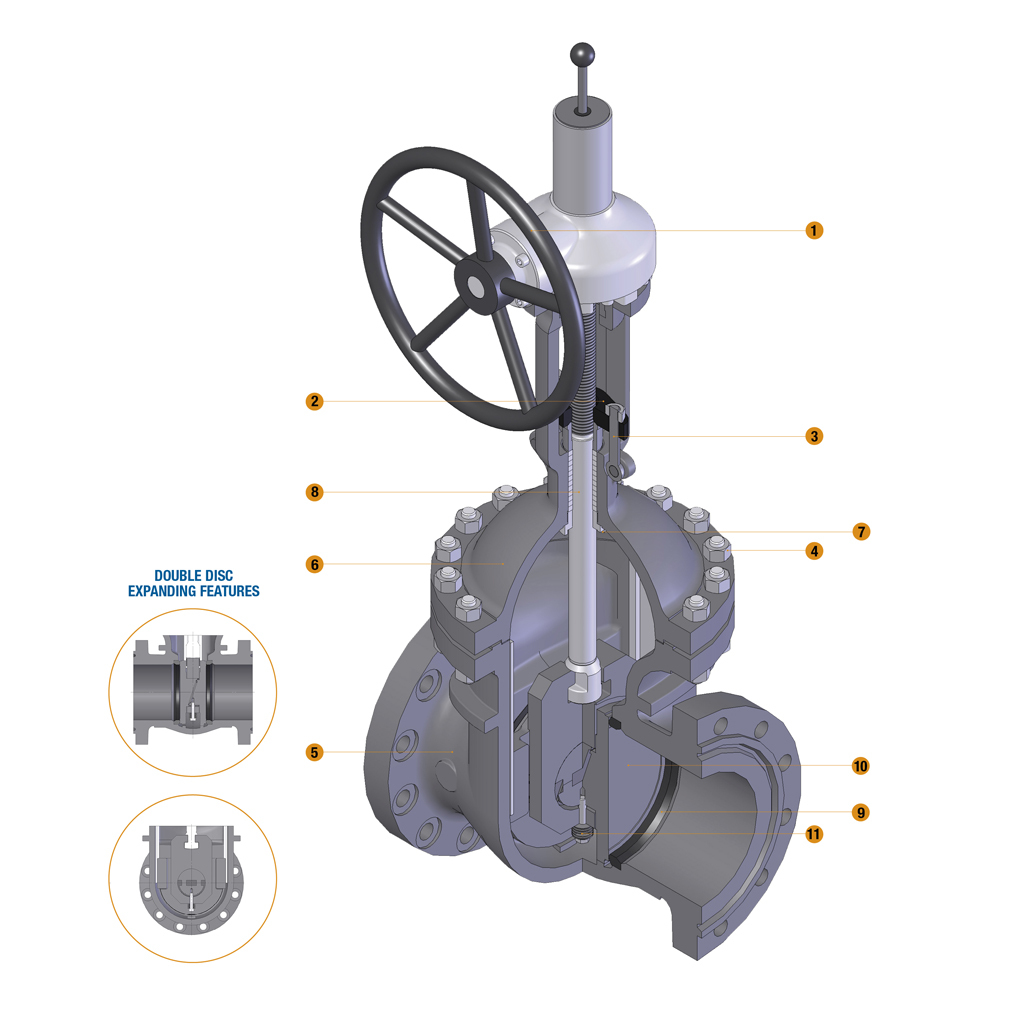

The spoked handwheel is fabricated from steel pipe. The hub is coupled to the yoke sleeve by means of a key. Larger valves are equipped with a bevel or spur gear gearbox unit.

They are in forged steel and are supplied in two pieces, self aligning design in order to allow the gland to slide parallel to the stem even if the eyebolts are unevenly tightened.

The forged steel gland bolts are of the eyebolt type which can be swung outward for ease of gland repacking. They are fixed to the bonnet by hinge pins.

Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard. The body to bonnet connection is designed according to ASME VIII DIV 1 standard

The body is in carbon, stainless steel or in CRA materials. The basic dimension, i.e. wall thickness, face to face and flanges comply with the relevant API and ASME standards. Body-to-bonnet flange is circular, except for Class 150 where it is oval. The body-to-bonnet joint are flat face for Class 150 valves, male-and-female on Class 300 and RJ on Class 600 and above. The body is basically supplied with renewable seats. Bosses are provided for drain taps or by-pass piping. The internal surfaces in contact with the fluid can be fully lined or cladded for improved corrosion or erosion resistance. Body “C” shaped guides are welded inside the body to drive the discs assembly during the travel action.

As the body, the bonnet is in carbon or stainless steel and is available in many other CRA. It is machined to accept yoke sleeve and incorporates a stuffing box sized in accordance with API standards. Lifting lugs can be provided integrally cast on the bonnet surface.

The bonnet bushing or backseat is in forged stainless and forms part of the trim. Special attention is given to its machining.

The stem is part of the trim and is available in a wide range of material in accordance to API 600 or customer’s requirements. The stem is provided with a T-shaped head. A ground backseat is provided to ensure a perfectly tight seal to the stuffing box when the valve is fully open. The thread is trapezoidal ACME type. All the stem sizes comply with the API 600 standard.

The rings are part of the trim of the valve. Welded-in seat rings are supplied as a standard. The two seating surfaces in the closed position provide a seal against pressure from both ends of the valve. They can be externally threaded and internally notched for easy installation and dismantling. Special attention is given to the seating surfaces which are ground and lapped for a tight seal.

The wedge effect between the two discs converts downward stem force into axial force and forces the parallel discs firmly against the valve seats, providing a seal against pressure at both ends of the valve. The central yoke ring forces one of the two discs during seating action and transmits the stem action to the disc assembly. It also keeps the discs aligned together during the travel.

Belleville springs packing ensures rapid unseating during opening operation.

Double Block and Bleed valves are capable to hold the pressure in both direction and having the body bled to atmosphere, but can as well trap the pressure inside the body cavity, with problems during opening or dangerous pressure build up. ORION strongly suggest to provide an automatic pressure relief system, internally (disc hole) or externally (pipe and check valve to the upstream), in order to avoid such occurrence. If no harmful/polluting fluid is interested, a normal automatic relief valve can be used to vent cavity to atmosphere.