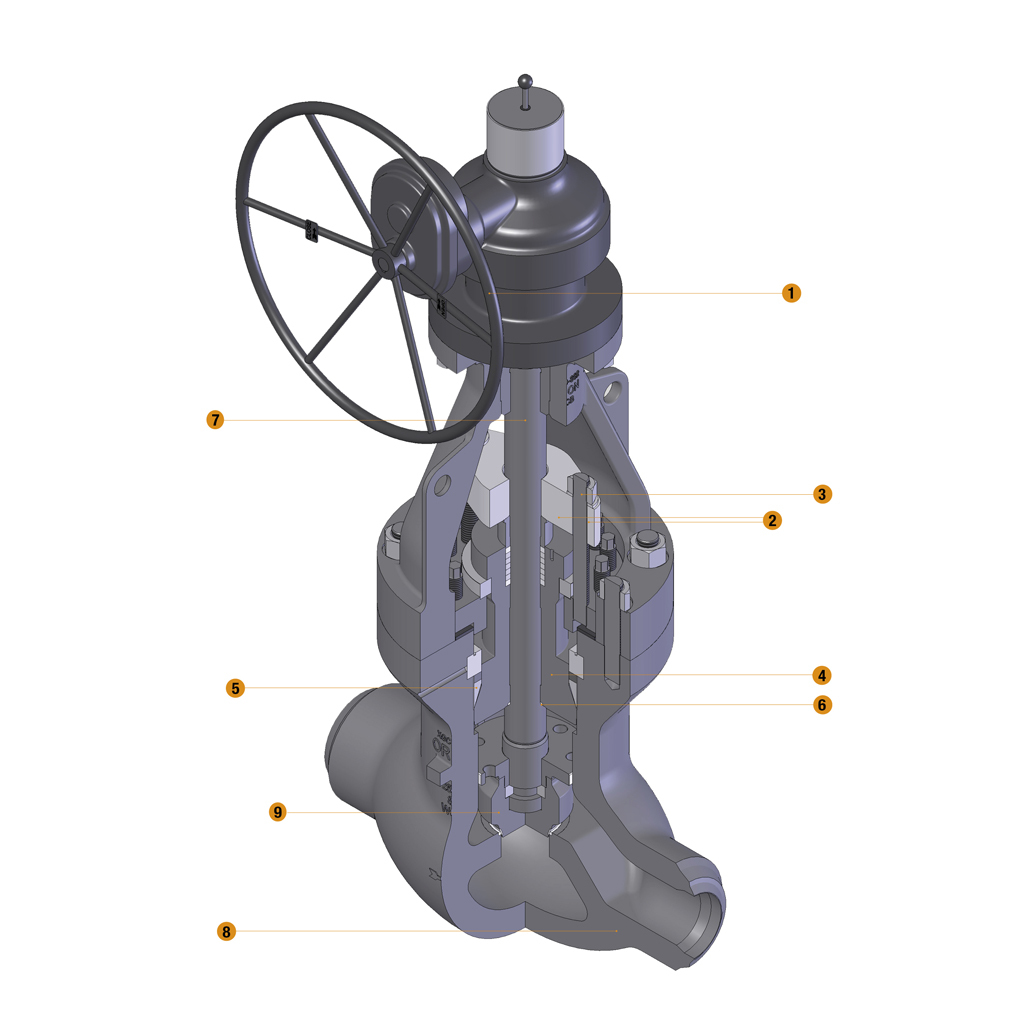

GLAND AND FLANGE

They are in forged steel and are supplied in two pieces, self aligning design in order to allow the gland to slide parallel to the stem even if the eyebolts are unevenly tightened.

Pressure seal valves are best fit for vertical stem / horizontal flow installation. Special cases can be evaluated and developed on request.

The spoked handwheel is fabricated from steel pipe. The hub is coupled to the yoke sleeve by means of a key. Larger valves are equipped with a bevel or spur gear gearbox unit.

They are in forged steel and are supplied in two pieces, self aligning design in order to allow the gland to slide parallel to the stem even if the eyebolts are unevenly tightened.

The forged steel gland bolts are of the eyebolt type which can be swung outward for ease of gland repacking. They are fixed to the bonnet by hinge pins.

It is machined in the same grade of the body or in superior alloys, if required. The pressure seal design keeps it tight to the body at high pressures even if bolts are loose or material dilatation occurs. It can be cast or machined from bar. It incorporates a stuffing box sized in accordance with the BS standard, and in case can be extended for very high temperature applications. A locking flange with a set of bolts pulls the bonnet outward, against the gasket, giving a preload for initial sealing between body and bonnet.

It is basically supplied in graphite for best fit up to class 1500 and in AISI 316L stainless steel for 2500, carefully machined to provide a perfect tight seal. Upon request, AISI 316L can be installed on every pressure rating. It is integral with the bonnet and hardfaced and will provide a perfect tight seal between stem and bonnet, which will allow emergency repacking operation even under pressure.

It is integral with the bonnet and hardfaced and will provide a perfect tight seal between stem and bonnet, which will allow emergency repacking operation even under pressure.

The stem is part of the trim and is available in a wide range of material in accordance to BS1873, API 600 or customer’s requirements. The stem is provided with a ground backseat in order to ensure a perfectly tight seal to the stuffing box when the valve is fully open. The stem is highly finished in order to minimize friction and prevent damage to the packing. The thread is trapezoidal ACME type. All the stem sizes comply with the BS 1873 standard.

The body is in carbon or stainless steel and is also available in many other CRA. It is carefully designed for total reliability and simple maintenance. The basic dimension, i.e. wall thickness, face to face, butt-weld ends and flanges comply with the relevant BS and ASME standards. The body neck is cylindrical in order to host the pressure seal bonnet. Disc guides are integral, and the seat ring can be hardfaced integrally or threaded and welded in the body. The connection ends are typically butt welding type for high temperature applications.

The disc is the main part of the trim. It is connected to the stem by means of a swiveling half rings coupling and is guided in the body from 4” and above. The standard sealing profile is a spherical surface seating against a conical seat. If required a conical to conical seating can be supplied, and for flow throttling operations a regulating disc is adopted, shaped in order to give a linear opening. The stop check execution shows an externally guided disc, disconnected from the stem. A cladding or lining can be applied to larger discs to improve its resistance against erosive and corrosive environments.