BODY BILTING

Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard.

Swing check valves are best fit for horizontal pipeline installation. Special cases can be evaluated and developed upon request. For small valve sizes, a vertical installation (only with upward flow) is still possible, but for heavier weights of discs chattering issues can occur. Dampers or counterweight shall be then provided.

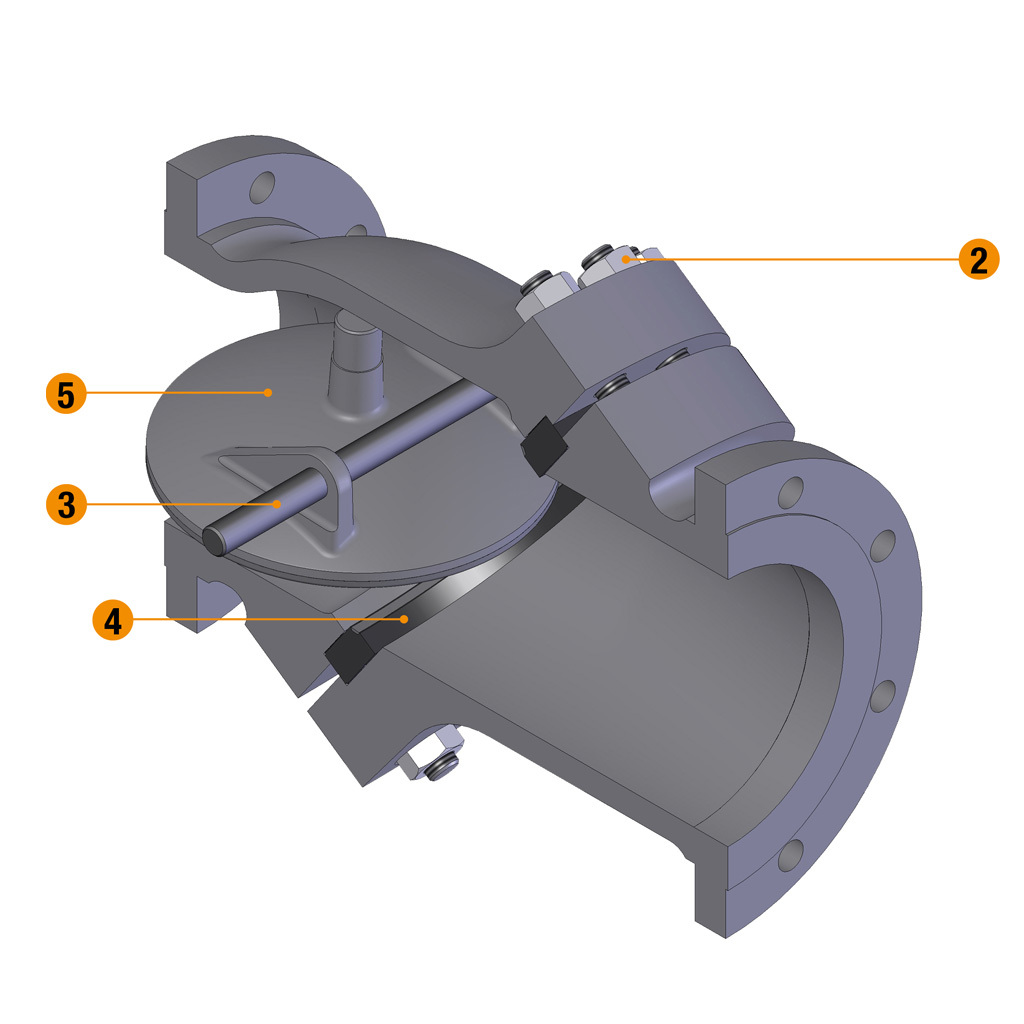

The body is in carbon or stainless steel and is also available in many other CRA. It is carefully designed for total reliability, to keep the pressure drops to a minimum and simple maintenance. The body shall be two-piece, consisting of an entrance and a discharge section bolted together at an angle with the pipeline. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant BS, API and ASME standards. Two threaded bosses are incorporated to ensure correct alignment of the hinge disc.

Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard.

The disc pins are part of the trim. They are in forged stainless steel machined from ground bar. The two disc pins are centred in position with two flanges and they can be easily removed for maintenance of the valve.

The rings are part of the trim of the valve Special attention is given to the seating face which is ground and lapped, for a perfectly tight seal.

The disc is part of the trim and it is in forged steel or cast steel. The disc is balanced so that as flow decreases, it will pivot towards its closed position, closing before reverse flow actually commences.The seating surface is ground and lapped.