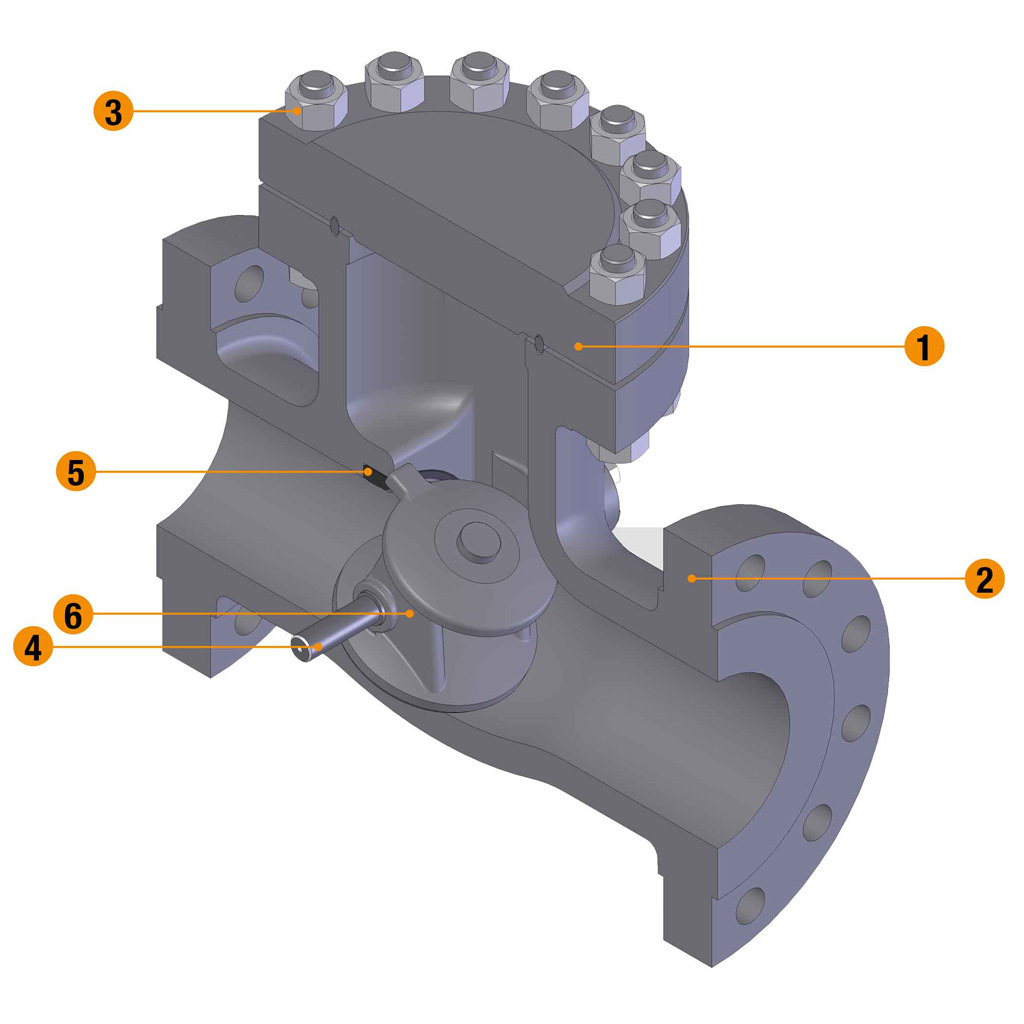

COVER

The cover is in carbon or stainless steel and is also available in many other CRA materials. The connection sealing surfaces are raised face or ring joint to suit the valve rating.

BODY

The body is in carbon or stainless steel and is also available in many other CRA. It is carefully designed for total reliability, to keep the pressure drops to a minimum and simple maintenance. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant BS, API and ASME standards. The body-to-cover flange is circular. The sealing surface for connection to the cover is recessed in the 150 and 300 Class and ring joint for higher ratings. The body is threaded for a renewable seat and an integral over-travel stop for the disc is incorporated. Two threaded or flanged hubs are provided sideways for the location of the hinge pins. Bosses are eventually provided for drain connections.

COVER BOLTING

Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard.

HINGE PIN

The disc pins are part of the trim. They are in forged stainless steel machined from ground bar. The disc pins are centred in position with two flanges and they can be easily removed for maintenance of the valve.

SEAT RING

The ring is part of the trim of the valve, and is supplied as welded-in as a standard. In case the outer diameter is threaded and its bore is notched to easy installation and dismantling. Special attention is given to the seating face which is ground and lapped, for a perfectly tight seal.

DISC

The tilting disc is part of the trim. The disc’s balanced design allows to keep it in the open position by a minimum fluid flow and lets this one to return to closed position quickly, before flow reversal starts, and so far not causing a sudden water hammer effect (non slam effect). The conical seating surface is ground and lapped.