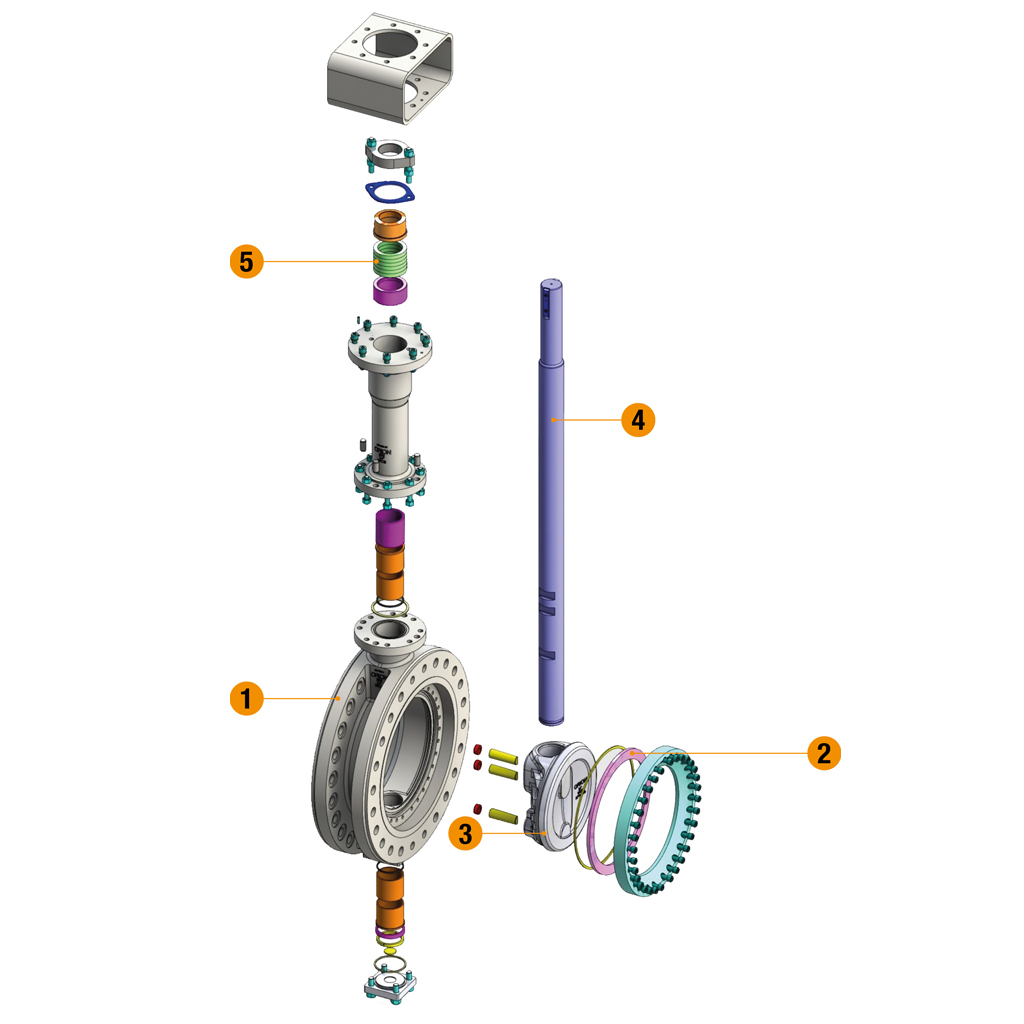

VALVE BODY

The body is cast in carbon or stainless steel and is also available in many other CRA. For severe services and large valve sizes it can be internally lined or fully cladded instead of having solid CRA. The internal profile is designed in order to minimize pressure losses, and basic dimensions (face to face and wall thickness) comply with API 609 and ISO5752 standards. Body style can be wafer or wafer LUG type, flanged, or buttweld. Body connections can be provided as per ASME B 16.5 RF or RTJ, as well as BW end or hub connection are available.

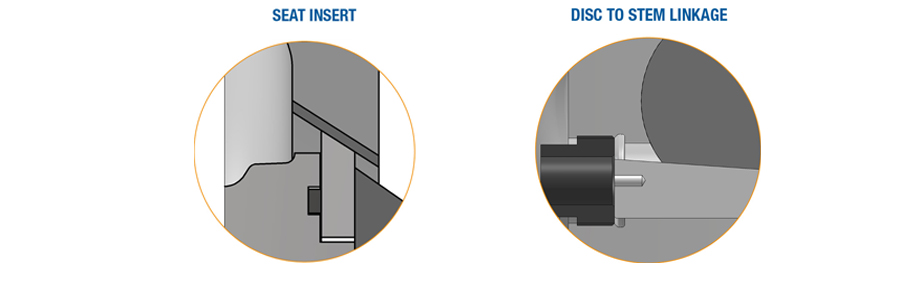

SEAT INSERT

The seat insert can be proposed with different solutions, against different service severity scenarios. A plastic (PTFE/PEEK/PA/...) insert can be chosen as well as laminated graphite/metallic inserts, for metal to metal seating.

The seat insert is located in the body, to enhance the tightness capability, been working in expansion only. For wafer style valves only, it is located on the disc.

Seating geometry is of triple eccentric type, ensuring the best result in terms of seating effort against tightness level achievable.

DISC

The disc is the main part of the trim and allows fluid control, as well as tight shut off capability. It comes in forged or cast steel ort CRA for diameters up to 12” and in cast steel for larger diameters. Its shape is optimized in order to avoid turbulences and is assisted by a spring in closed position. Each component is verified with Fem-FEA analisys in order to deliver the seating torque uniformly to the seat and ensure the highest rigidity against both seating directions.

STEM

The valve is operated through the stem rotation, which hold the pressure thrust and increase the disc stiffness. Stem is connected to the disc through non-shear pins, which increase the torsional resistance of the stem and do not transmit the torque through shear resistance of the pins.

STEAM SEAL

The stem is sealed through an O-Ring arrangement for regular temperature applications and mild environments. An energized lip seal is used for low torque demand and/or cryogenic services. For high temperatures, fire safe design, or when a stuffing box is preferred, a graphite packing is provided, with the top level FE qualifications in order to reduce fluid losses.