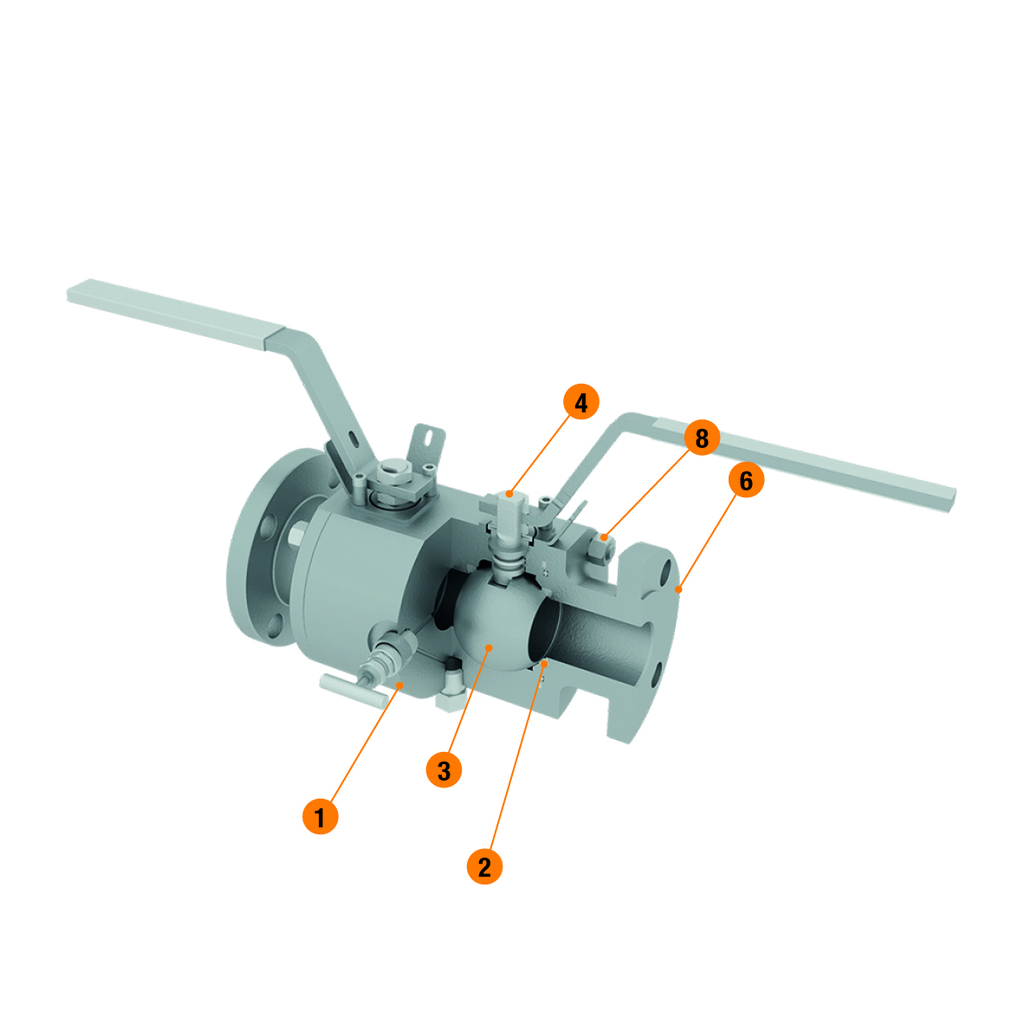

BODY

The body is forged in carbon, stainless and other CRA steels commonly used in the O&G industry such as Duplex, Super Duplex and Nickel Alloys. Its design is in compliance with the relevant API and ASME Standards. The upper part is machined to integrate ISO 5211 coupling. The body encases two balls (Block) with a Needle valve (Bleed) in between. The bleed outlet is a plugged ½” NPT connection as a standard. The body is provided with a double-sealing system, made of a primary gasket (0PTFE or O-Ring) and a Graphite secondary seal for a fire safe design.

SEAT RINGS

Seats are machined from a solid thermoplastic ring and encapsulated in a specially machined pocket in the body/closure for longer life. The material is selected based on valve pressure/temperature design data in order to grant the best performance under any conditions. For special services (slurry, presence of solids, high temperature) the soft seat can be replaced by a metal ring hard faced with Tungsten or Chrome Carbides Coating (Metal Seated).

BALL

The ball is supported by the seats allowing a slight floating movement. Because of this design, the fluid pressure acts on the upstream side of the ball producing a positive seal of the same against the downstream seat. In case of a perfect balance of the sealing elements, a pressure equalization of the body cavity is possible. The ball makes a 90° movement from the fully open to the fully closed position driven by the stem connected to a slot in the ball. Its circular opening allows for minimal pressure loss. In metal seated execution the sealing area of the ball is also coated with Tungsten or Chrome Carbides and lapped with the seats to obtain a tight sealing.

STEM

The stem is designed to comply with relevant API Standard requirements. It is inserted from inside the body to connect with the operator and its shouldered design ensures that it cannot be ejected by the internal pressure (Anti Blow-Out). It houses the stem sealings, either elastomeric O-Rings or thermoplastic Lip Seals, designed to meet the most stringent Fugitive Emissions requirements. A Graphite ring integrates the set of sealings as a Firesafe barrier.

CLOSURES

The closure is bolted to the body by means of fully threaded studs and nuts. It is machined to the specified ends (Flanged, Butt Weld, Hub ) for connection to the line.

BODY BOLTING

Body studs and nuts are supplied in materials according to ASTM standard and can be coated to any special requirement.

BLEEDER

The Bleeder is a Needle valve bonnet assembly connected to the cavity between the two block valves. It performs the function of bleeding the fluid inside the valve through the bleed connection. As a standard it’s a T-Bar operated valve screwed into the valve body. Other options are available like bolted design, OS&Y, Handwheel .

OPTIONALS

Locking plate / device can be provided upon request