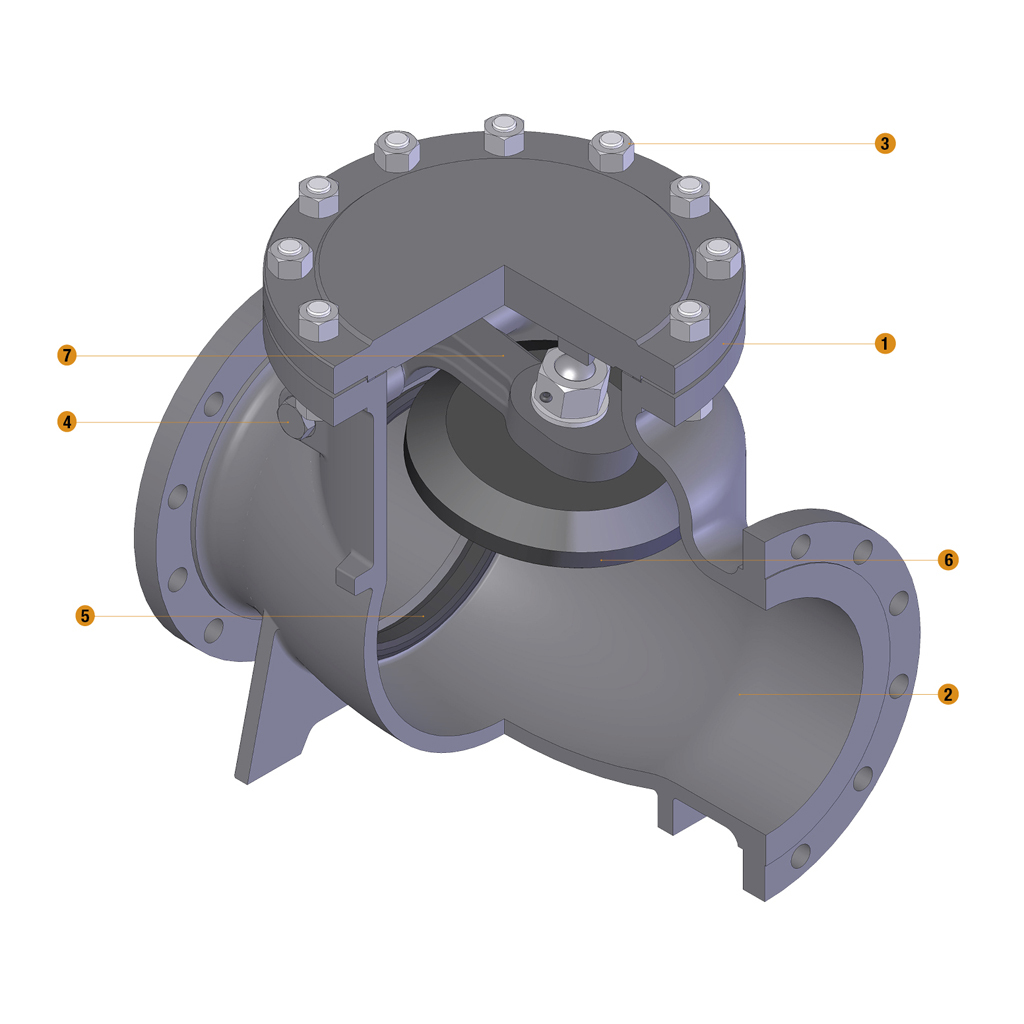

COVER

The cover is in or forged steel. The connection sealing surfaces are raised face or ring joint to suit the valve rating.

BODY

The body is in carbon or stainless steel and is also available in many other CRA materials. It is carefully designed for total reliability, to keep the pressure drops to a minimum and simple maintenance. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant, ASME and API 6D standard. The body-to-cover flange is circular. The sealing surface for connection to the cover is recessed in the 150 and 300 Class and ring joint for higher ratings. The body is threaded for a renewable seat and an integral over-travel stop for the disc is incorporated. Two threaded bosses are provided for the location of the hinge pin. Bosses are eventually provided for drain threaded connection. Standard “full opening” design allows for passage of scrapers and spheres.

COVER BOLTING

Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard.

HINGE PIN

The hinge pin is part of the trim, in forged stainless steel and is machined from ground bar. The hinge pin is locked in the body with two threaded NPT plugs. The pin can be easily removed for maintenance of the valve. The pin can be replaced by a grooved shaft capable of giving control to the disc from the external. For instance, an hydraulic damper can be installed to avoid chattering, or a lock-open lever can be provided, as well as an external counterweight.

SEAT RING

The rings are part of the trim of the valve. Welded-in-seat ring are supplied as a standard. In alternative, the seat outer diameter can be threaded and its bore is notched for easy installation and dismantling. Special attention is given to the seating face which is ground and lapped, for a perfectly tight seal.

DISC

The disc is part of the trim and is in forged or cast steel. On the back face there is a threaded spigot for the connection to the hinge arm by a nut and cotter pin. The seating surface is ground and lapped.

HINGE

The hinge comes in forged steel for small diameters and in cast steel for valves from 14” upwards.